Blog

Can Carbon Fibre Be Repaired?

Posts by : Dan McKenzie | 01/01/2024

A common question we get asked is, “can carbon fibre be repaired?”. The short answer is yes, we can indeed repair carbon fibre!

Although carbon fibre has been around for decades in both road going vehicles and racing/performance machines, it’s still relatively unknown that carbon fibre can actually be repaired. There are a few occasions when carbon shouldn’t be repair but for the most part, this is very much a cost effective way to get a nice looking carbon fibre part back to it’s former glory. So let’s dive in and discuss this process in more detail and how Carbonwurks could potentially save you time, money and recover a part that may be difficult to replace.

Initial process of inspection

For any repairs we undertake, we ideally need a good selection of images or video showing the damage to the part and some overviews to give a good idea of what is required. We can then quote based off this before we get stuck into the repair itself. We normally undertake all carbon repairs in component form meaning the part needs to be removed from the vehicle.

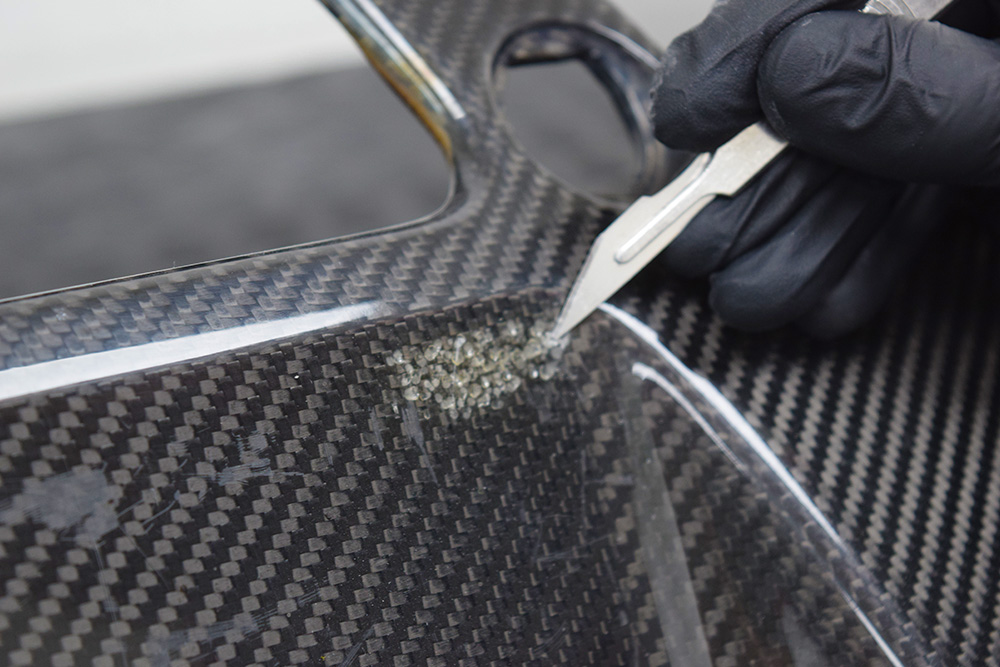

Strip down

Before making things better, they often have to look worse, this is very much the case with carbon fibre. Most carbon parts are lacquered and will have resin in-between the lacquer and carbon. To get to the route cause, we need to very carefully strip the surface before getting to the carbon itself. This is one of the most challenging parts of a repair as if the sanding process is too aggressive, the carbon weave (or other composite substrate) can be damaged which is impossible to bring back without re-skinning the part.

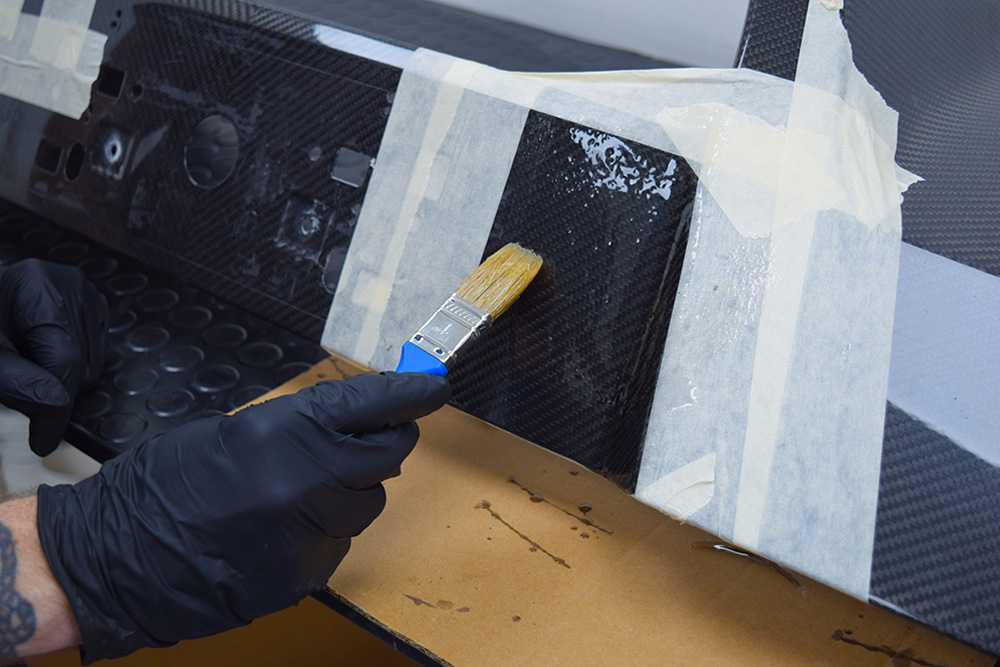

Rebuilding

Depending on the extent of the damage, the rebuild process can be a simple resin infusion to bind damaged weave substrates together or for splits, cracks or holes, further reinforcements will be required to ensure the part is structurally sound. When reinforcing the part, it’s import to select the right material and to bind this properly to the structure to give a solid finish. We tend to resin infuse any cosmetic finish to give the best end result and to smooth the surface ready for clearcoat. With heavier damage it can be difficult to achieve a cosmetically perfect repair, fortunately we have a wealth of knowledge and skill to bring back a carbon part in an efficient, cost effective and technically correct process which gives great aesthetic results.

Finishing touches

Most carbon parts we manufacture or repair are lacquered. We can achieve standard gloss, satin or matte finishes and in recent years we have also been able to finish carbon in a variety of coloured tints too for that unique and special look. The main reason for lacquering carbon is to protect it from the elements and the potential of damage from general wear and tear. Carbon by nature is not UV stable and adding protection ensures the stability of the part and stops discolouration too.

Before

After

We have captured a handful of carbon repairs that are viewable on our Youtube channel, if you are contemplating this route, it’s worth seeing what’s involved in the process. If you would like to get in contact with us about a potential repair, please get in touch through our website contact form – Contact Form