Coloured Finishes for Carbon Fibre

Specialist Carbon Fibre Coloured Finishes

Making Your Carbon Fibre Parts Even More Unique

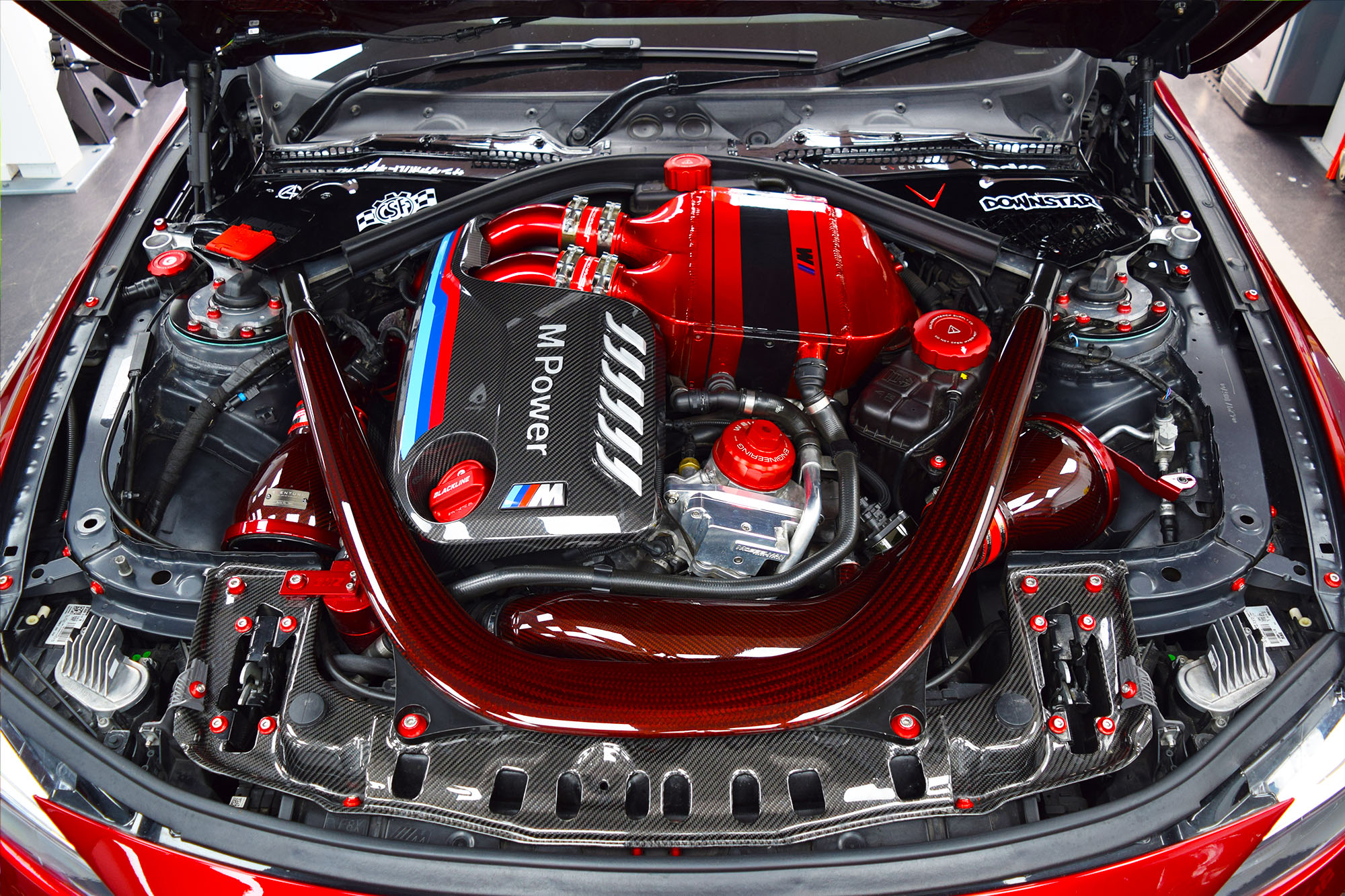

Here at Carbonwurks we like to be able to offer a large range of services that to most, would be unachievable. We have been producing carbon fibre for getting on 15 years and have been striving to offer the most unique finishes and fabrics the world has ever seen to create some truly special components.

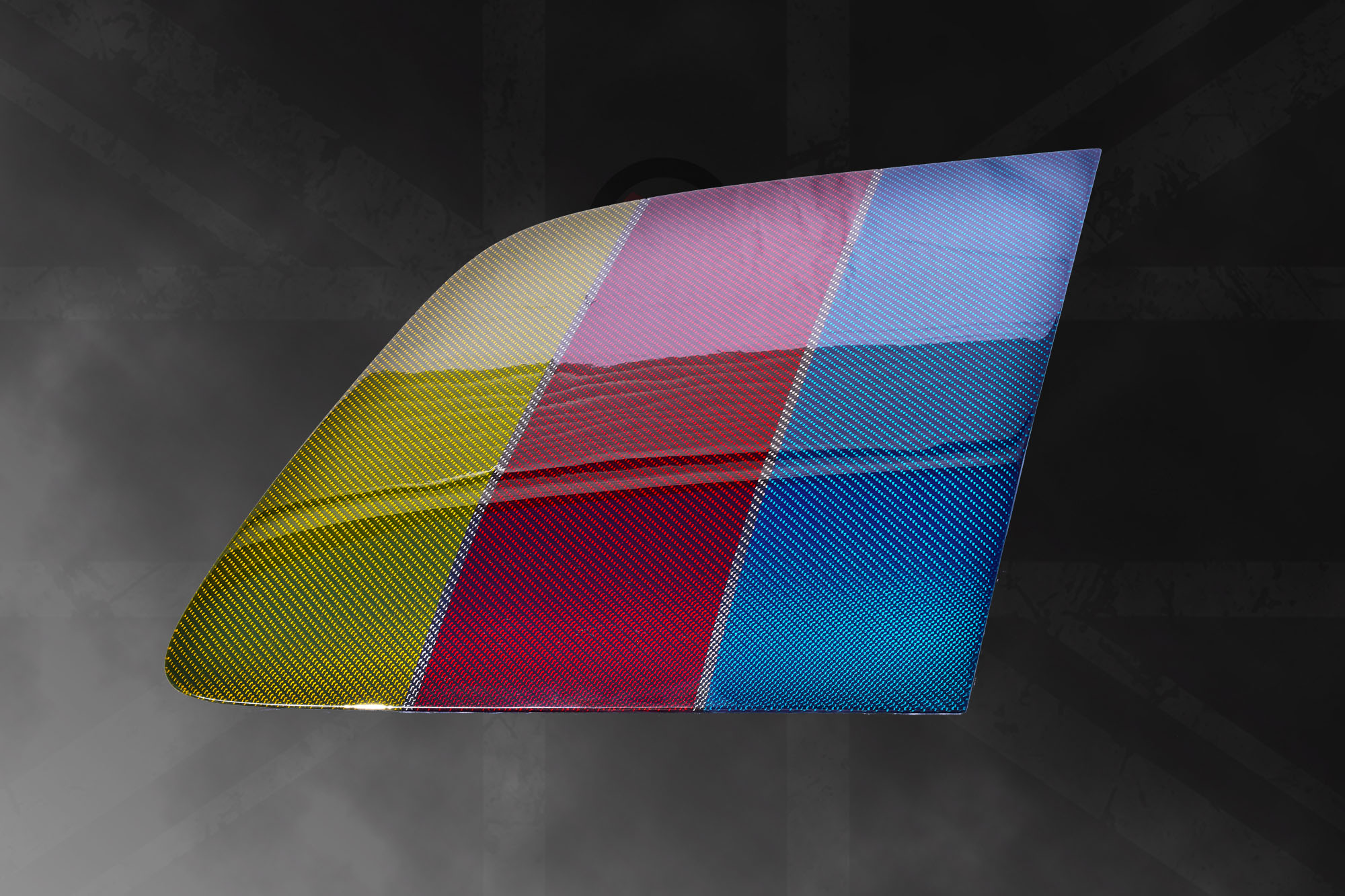

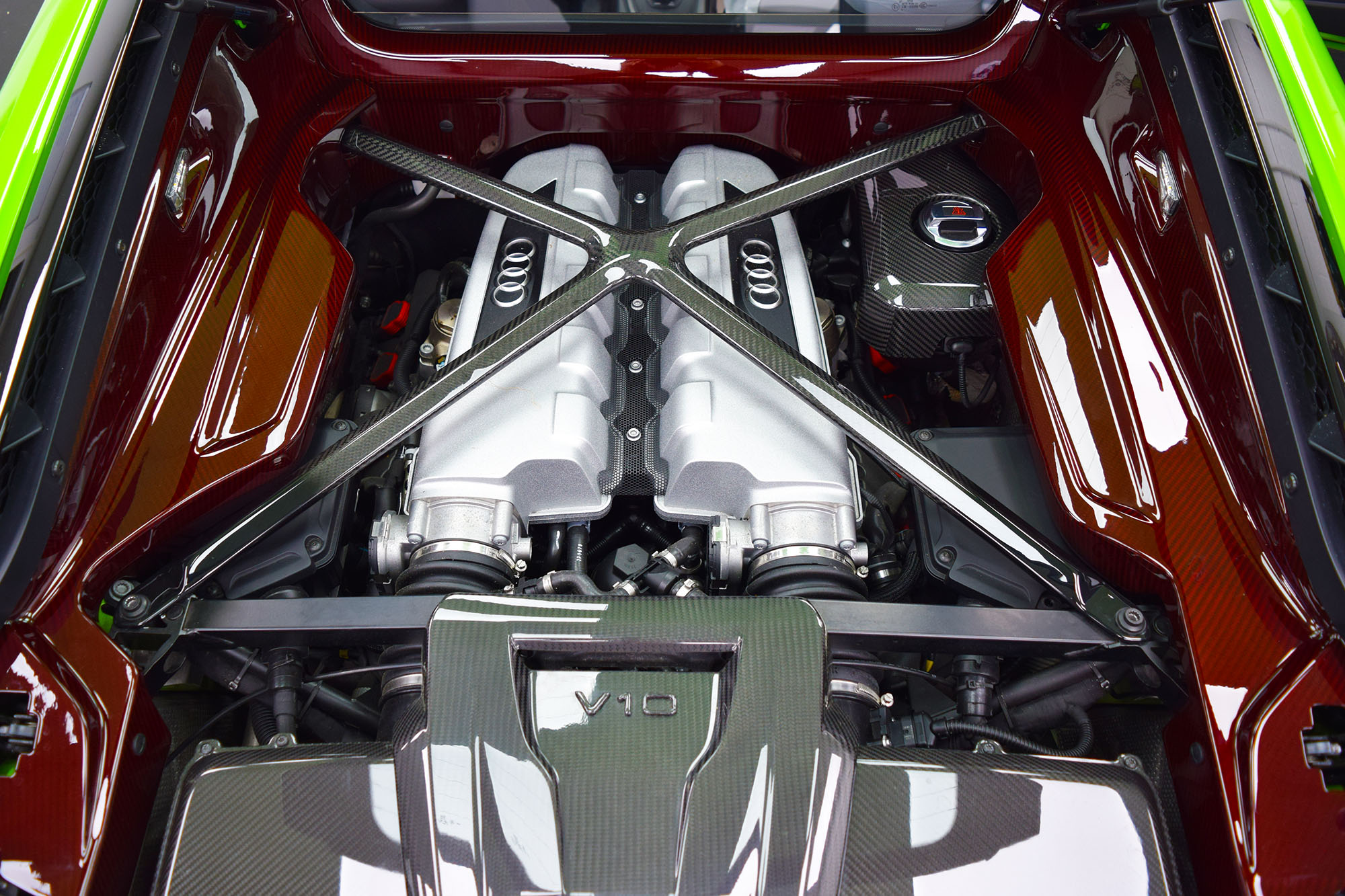

One of the things we can offer to either new carbon fibre parts or existing carbon fibre parts is tinted colour finishes. We have carefully selected a choice selection of candy tinted finishes to give a colour change to the standard black carbon fibre finish. We can also tint other types of composites too includes silver fibreglass/carbon and Kevlar’s too.

The tinted finish is achieved in the lacquering process to obtain a different colour carbon fibre. We can offer a range of different colours, a few examples of these are as below.

With tinting carbon, we can’t always guarantee a specific hue or colour (matching to a paint code or colour). If you are wanting a specific colour, please get in touch to discuss this further to see if we can cater. We generally would recommend tinting carbon parts in batch to ensure a good uniform finish across the parts. If you wanted to stagger the timing of several parts, this would not be advised as although ratios are set, how the part is layered can change the colour on the part itself.

Lead time will depend on the parts being re-finished. Generally, the process takes 2-3 weeks to complete. Cost will depend on the parts being worked on, we sadly can’t give a blanket price as every part is different in shape, size and complexity. We do also have to spend time to ensure the part is ready to be refinished in a tinted colour which can very much vary depending on the age and production method of the part in question.

About The Process

Things To Note

- If we are offering a tinted finish to a part we already produce, this process will be more cost effective as will require less preparation time. The same can be said with any brand new parts.

- If the parts are in a used condition and are showing signs of general wear and tear, this will add complexity and time to prepare the part properly. Stone chips and light scratching are easier to prep but if your part you are wanting to re-finish is damaged, it might be worth having a look at our repair page which outlays the process involved in repairing carbon. We can offer a full restoration process for your carbon fibre.

For any carbon repairs, please check out our page which can be found here:

so here's what's

Needed From You!

Pictures of the part

We’ll need high quality images of the part in question, ideally close ups of the areas being tinted or lacquered and some overview images to give us an idea of scale. Please ensure you take as many pictures as possible from different angles.

Send over the pictures

Once you have all the images you can email them to us at [email protected]. If there is a lot or the files are too big then your best solution is to put them all into a folder, zip / archive them and send them to our WeTransfer Account – WeTransfer.com

Vehicle Info

When you send the photos it would be great to include as much information about the vehicle as possible such as Make / Model / Year / Reg or VIN Number.

Once we have all of the above our team of fabricators will look over all the information provided and then come back to you with costings and timescales involved.

Please try to be as accurate as possible with the pictures and the information provided as if we don’t get all the facts prior to the part arriving it may be that extra time and materials may be required which will increase the costs.

The next step is to get in touch with us using our contact form below:

Frequently Asked

Questions

Sadly, this isn’t completely possible. We can try and get a similar colour, but paintwork is sprayed over a base colour which is normally much lighter than carbon fibre which is very dark. We can try and compliment the colour or have the carbon as an accentuating/contrasting colour.

Absolutely! We will have to prepare the parts properly so they are ready for the process which will come at a cost but we can still refinish in a different colour of choice.

We do repair a lot of carbon fibre and as part of the process, we will lacquer the component itself. In this stage we can add a tinted finish. The repair element is charged separately to the coloured finish however.

It comes down to the size of the part. The colours themselves we use are priced the same, it will just be down to how big and complicated the part is and how much preparation work is required.

Once the part is finished, it should be treated like any painted and lacquered part. Polishing and waxing the finish will keep a good level of finish and ensure longevity. PH neutral cleaners should only be used on the surface, no acid or alkaline based cleaning products should not be used!

It will depend on the condition and size of the part. We will discuss lead times with you which will depend on our production schedule. We try to turnaround most parts within 2-4 weeks of taking receipt.

We can sometimes obtain a colour code from the tint used at manufacturer level. This isn’t always possible, however. If we are trying to achieve a similar colour tint to the factory finish, we can send out colour swatches for you to compare. This is a chargeable service, however.

Technically yes, although the colour won’t show through as much due to the depth being lost with no gloss level. The colour in the carbon would be very subtle.