McLaren Carbon Fibre Repair

McLaren Carbon Fibre Repair

Giving Your McLaren Carbon A New Lease Of Life

McLaren are known for some of the highest performing supercars this world has to offer. In recent years a lot of McLaren chassis’ are made entirely of carbon fibre and sport a huge amount of exterior and interior carbon fibre too. The whole ethos of McLaren is to save weight and create the most engaging, quickest lap timing cars possible. Sadly, with that much exposed carbon fibre it is common for accidents to happen which is where here at Carbonwurks we can help aid if that time ever comes.

Whilst every carbon fibre piece is unique and every damage is different this will massively influence the time involved for the repair as well as the costs.

As we are repairing more high performance carbon fibre than we ever have done, we wanted to really drill down into some of the repairs of these parts to show case the before and after of them as well as explaining what’s involved in the repairs. Below are just a couple of examples of McLaren Carbon Fibre Repairs that we have completed recently and a brief explanation about what happened and what was involved with the repair.

We can within reason repair any carbon fibre part on any McLaren from exterior parts such as front splitters, rear diffusers, side skirts & rear spoilers to interior parts such as centre consoles & dashboard trims.

McLaren 600LT

£185,500, 2020, 3.8 L Twin-Turbocharged V8 Engine, 600PS

Front Carbon Fibre Bumper

Original Part Cost: £11,500

Repair Time: 8 Days

- This particular repair is part of a series of repairs from the same car. It sadly had repeated hits to the underside of the car, each time catching different areas of carbon fibre.

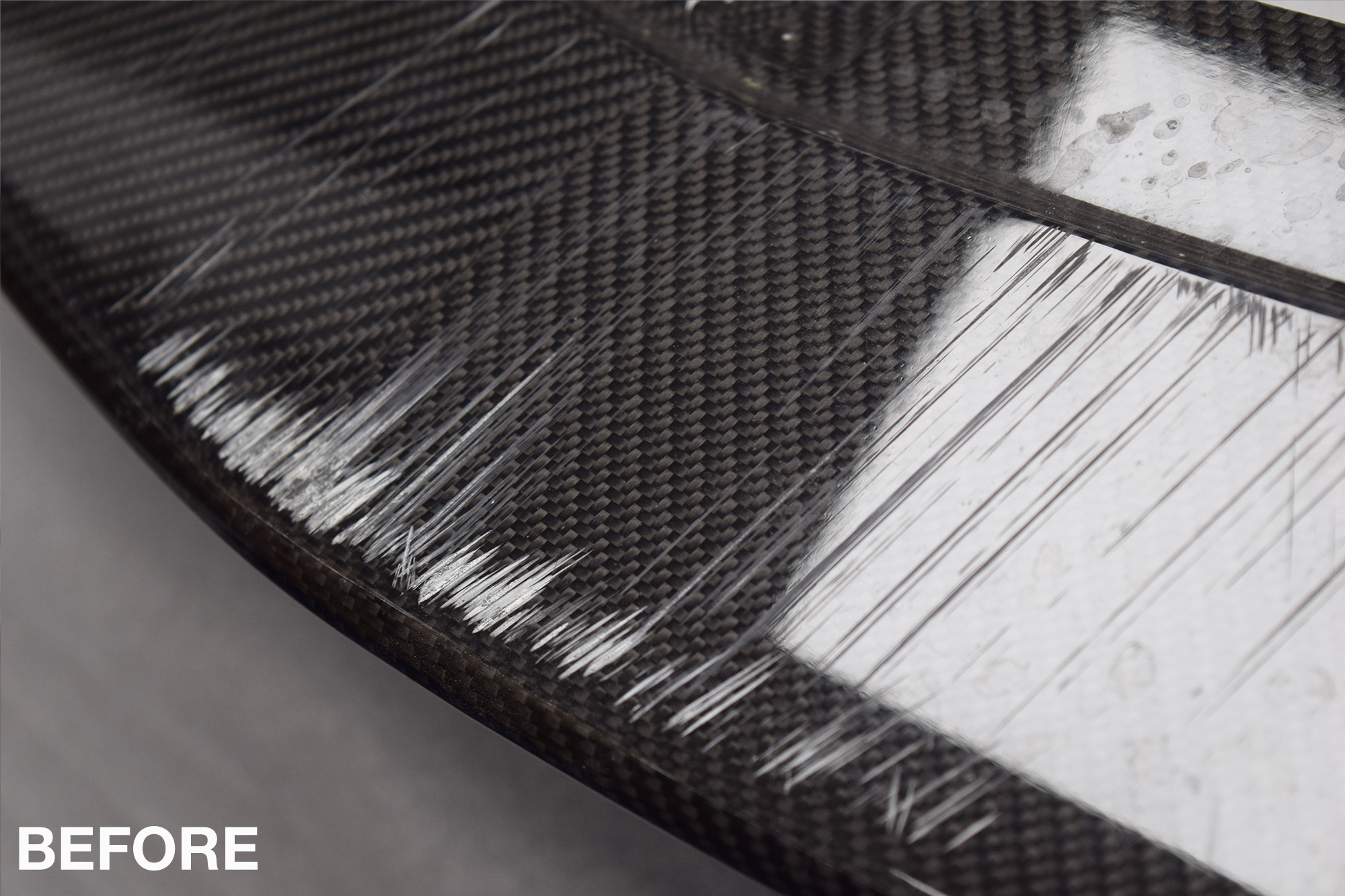

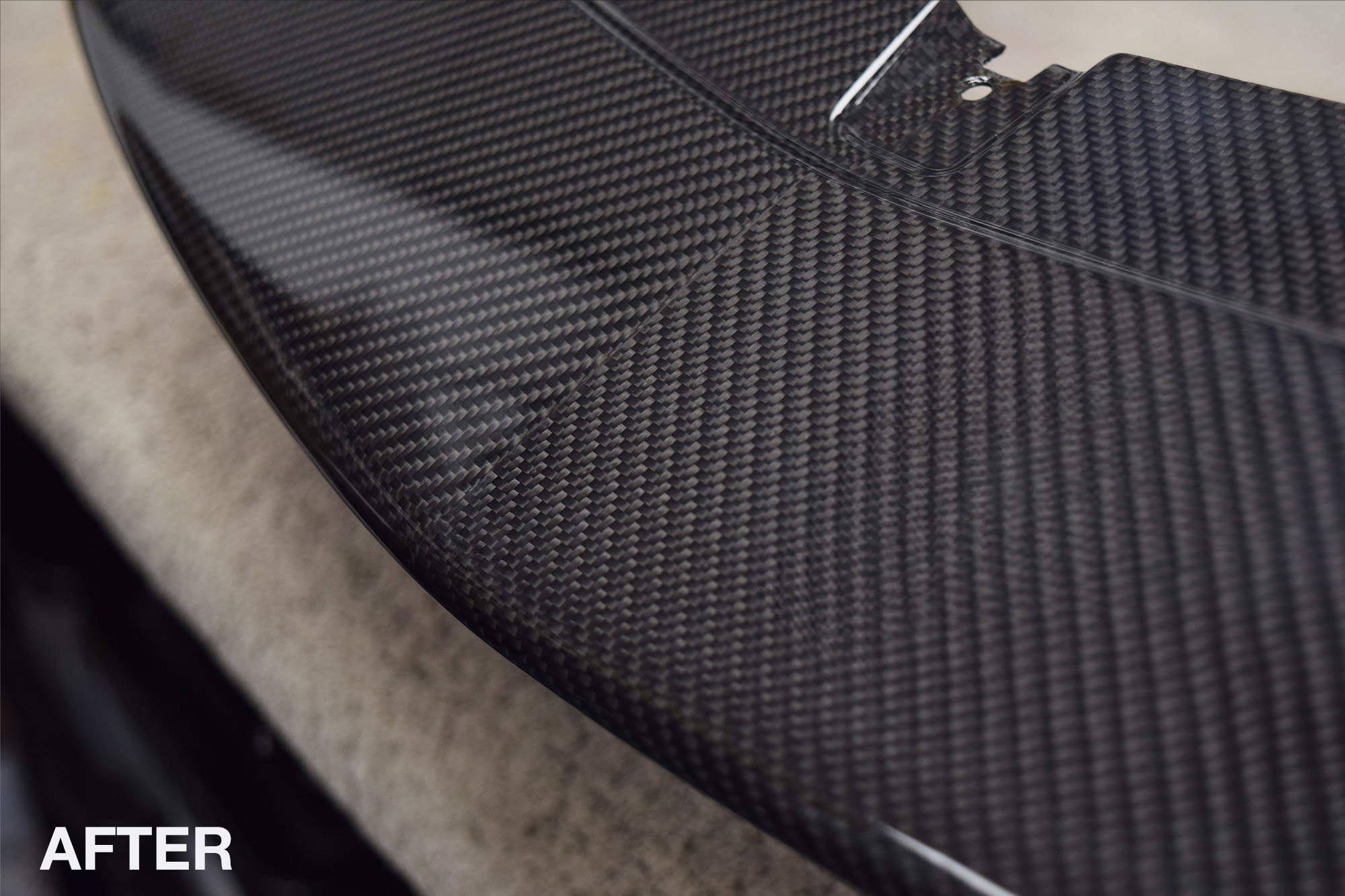

- This middle front bumper is quite a large panel, the damage was mostly superficial. With any carbon part, we strip down the lacquer and resin to get to the carbon fibres themselves so we can address any damage first before making the carbon cosmetically perfect.

- The panel had several reinforcement layer put on the inside to give strength and to resolve the weaker areas in the structure itself. Once reinforced, the rest of the carbon was addressed to level and smooth the finish before heading to lacquer.

- With all lacquered carbon parts, we flat and polish the finish to give as best as possible shine and obtain surface smoothness. The end result speaks for itself.

Scroll through the Before & After pictures of this McLaren 600LT Carbon Fibre Front Bumper

Front Carbon Fibre Bumper – Front Canard

Original Part Cost: £3200

Repair Time: 9 Days

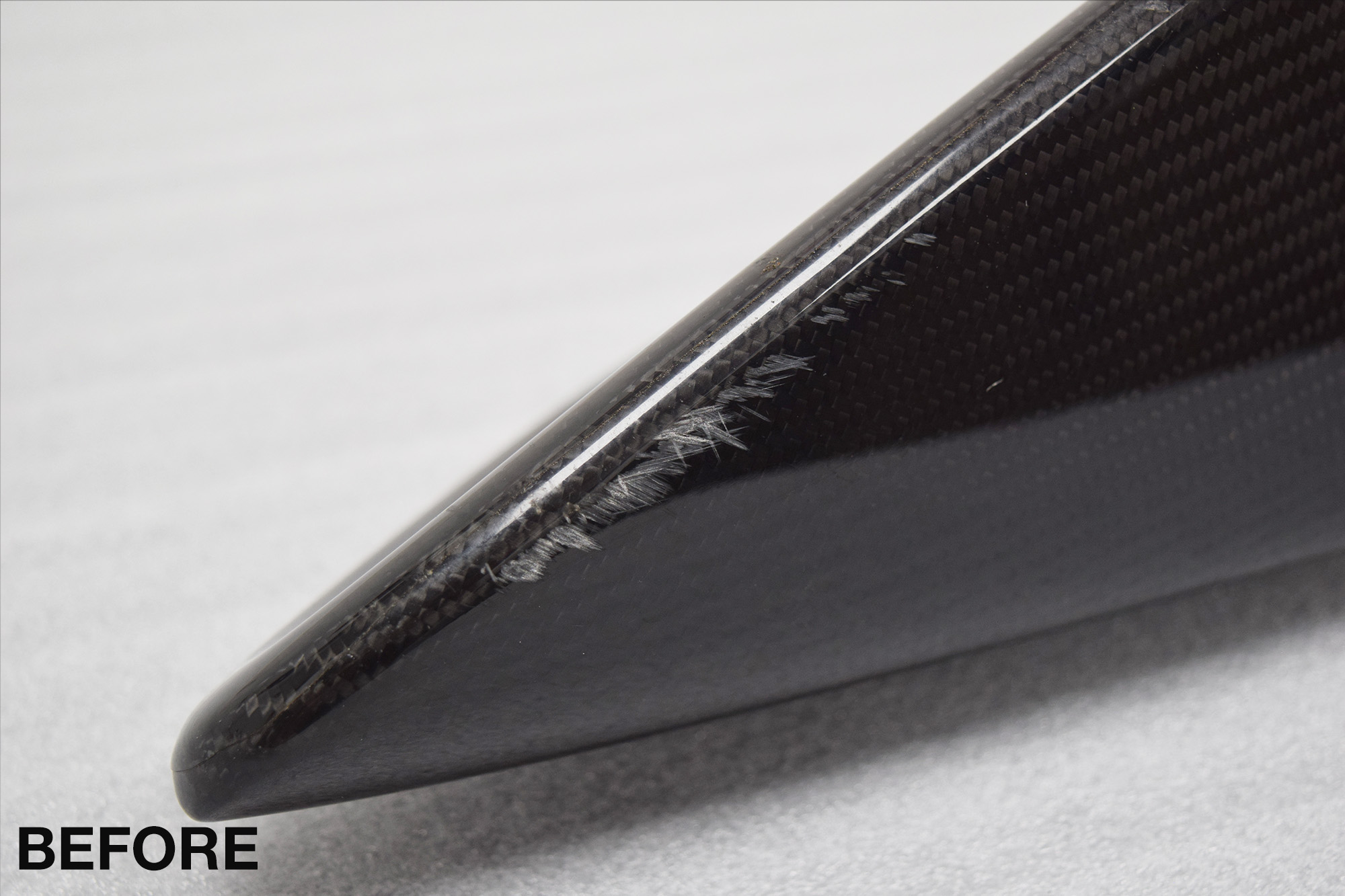

- Following on from the main middle front bumper panel, this side canard was struck quite hard which fractured through the part and created a reasonable amount of damage.

- As with the bumper, the canards was stripped down to access the damage carefully. With tight tolerances with the bumper behind, we had to be mindful of how much reinforcement we could use as so the canard would still fit correctly when fixed back onto the car.

- The inside of this part was reinforced with a lightweight and tightly woven fabric to allow for the most coverage without padding out the part.

- Once reinforced we addressed the cosmetic elements to this part before sanding down and being lacquered.

Scroll through the Before & After pictures of this McLaren 600LT Carbon Fibre Front Bumper Canards

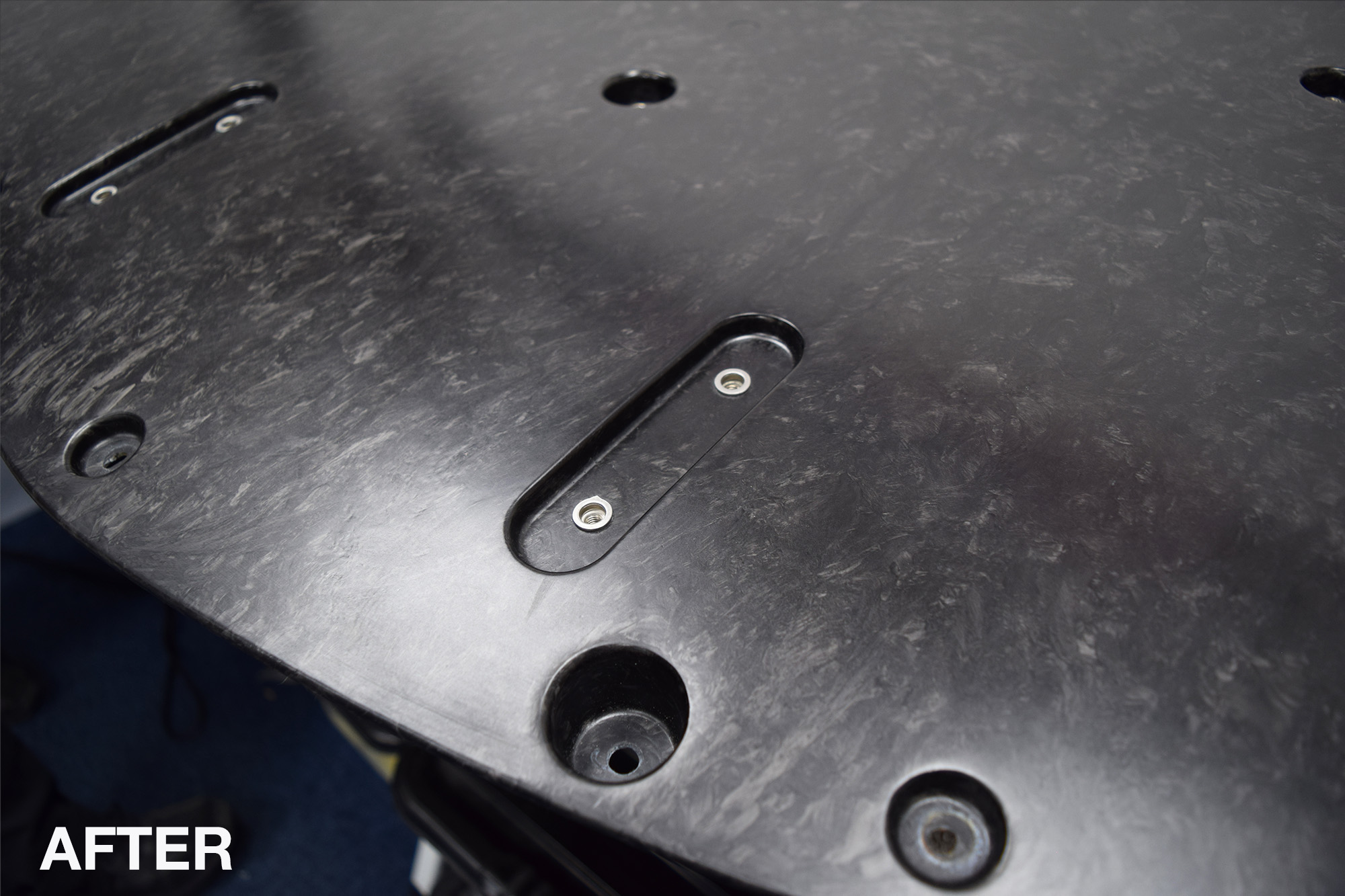

Forged Carbon Fibre Undertray

Original Part Cost: £4000

Repair Time: 6 Days

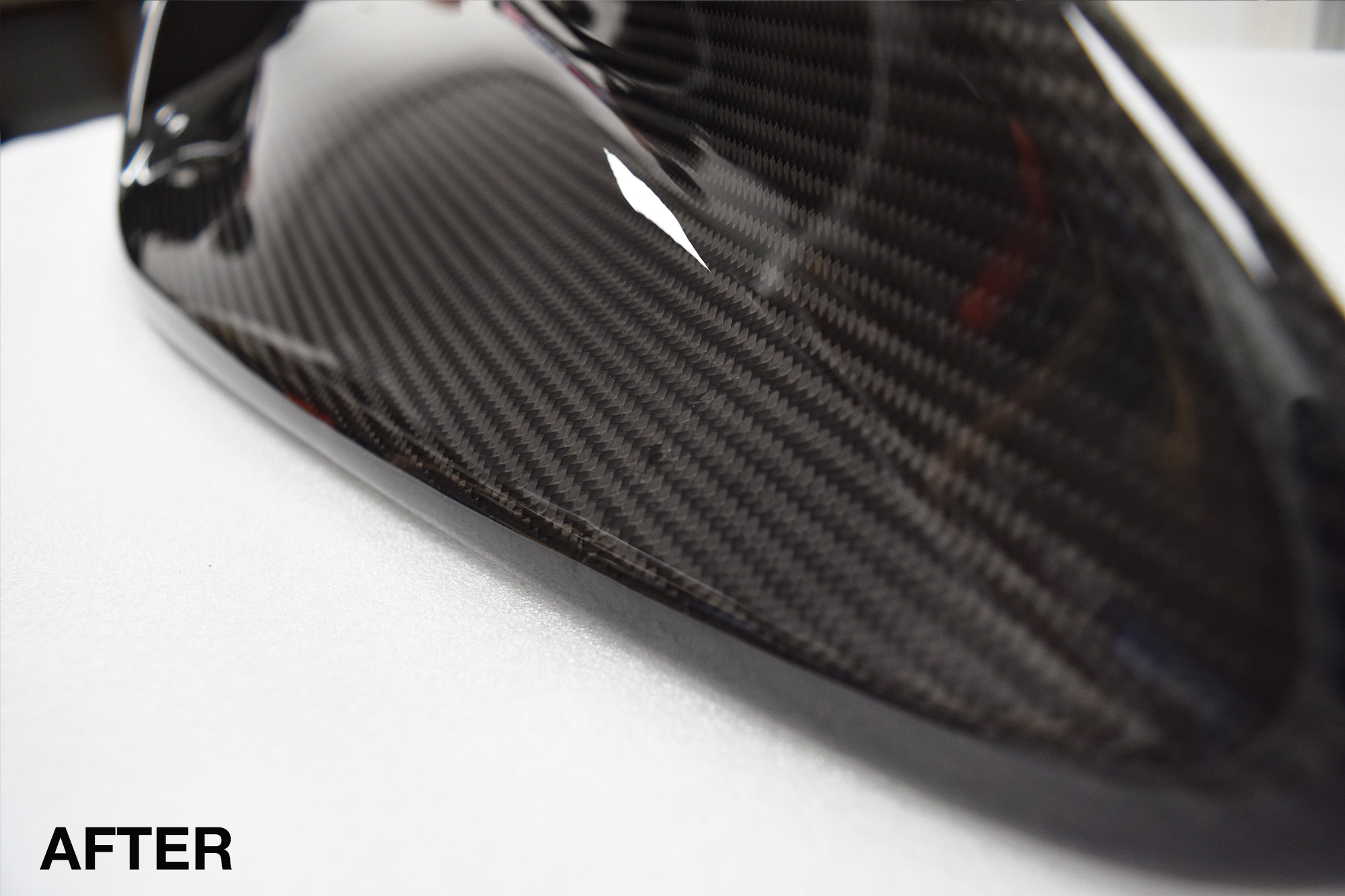

- With the front bumper section and undertray having been addressed, it was time to turn our attention to the undertray. This got away with a light amount of damage due to McLaren cleverly installing wear blocks under these cars to protect the carbon from getting worn out too quickly. An idea used in modern day F1 cars.

- Once the blocks had been stripped, we could rebuild the scuffed sections with resin infusion.

- Fortunately this panel did not need any reinforcement layers or patchwork which helps keep an original finish which is hard to replicate on this part – being forged carbon fibre.

- As with all repairs we re-lacquer to give the best finish and longevity against harsh environmental elements.

- Originally made in Britain and now repaired in Britain too by ourselves.

Scroll through the Before & After pictures of this McLaren 600LT Forged Carbon Fibre Undertray

McLaren 600LT Carbon Fibre Front Bumper Repair

so here's what's

Needed From You!

If after reading all the above you want to proceed with getting us to repair your damaged McLaren carbon fibre part then we’ll need a few things:

Pictures of the damaged part

We’ll need high quality close up and far away pictures of the item in question so we can see the damage and the overall part. Please ensure you take as many pictures as possible from different angles. If the damage goes through the part then we’ll need to see the rear also

Send over the pictures

Once you have all your pictures you can email them to us at [email protected]. If there is a lot or the files are too big then your best solution is to put them all into a folder, zip / archive them and send them to our WeTransfer Account – WeTransfer.com

Vehicle Info

When you send the photos it would be great to include as much information about the vehicle as possible such as what McLaren it is along with Year / Reg or VIN Number. We’ll also need to know how the damage initially occurred.

Once we have all of the above our team of fabricators will look over all the information provided and then come back to you with costings and timescales involved.

Please try to be as accurate as possible with the pictures and the information provided as if we don’t get all the facts prior to the part arriving it may be that extra time and materials may be required which will increase the costs.

For some of the more serious damaged parts it may be that we can’t offer any quote or timings until we have physically seen the item. There is also the possibility that the cost of repair is not financially feasible but we will certainly try to cater as best as we can.

The next step is to get in touch with us using our contact form below:

Frequently Asked

Questions

Often when carbon has damage, the fibres themselves can be fractured and torn. We can bind the part back together along with making it structurally sound but normally if the carbon has suffered cracks, splits or is missing carbon, there will be what we call a “Witness” mark. The best way to think of it is tearing a hole in your jumper, you can stitch it back together, but you may still see a small line where the fabric has been bound back together. Most of the time the witness mark is very small and unnoticeable, other times it can be slightly more obvious depending how bad the damage was. Regardless of this, the end result is as good as can be achieved and saves considerable amounts over replacing the component.

Generally, most repairs do look very good and, in some cases, do look brand new. To re-skin the entire part can be very complicated and very expensive. We try not to go down this route as it’s not always cost effective to do so. We work around the carbon that is there to give the best possible outcome. It’s rare that we would need to consider re-skinning the entire part.

The short answer is yes. We can fabricate small sections and if you still have the snapped off or damaged carbon, we can often make use of this. Depending on the part and the desired end result, sometimes this isn’t cost effective or viable but all the same, this is a type of repair we carry out often.

Very much so. We offer a range of different tinted finishes so if your carbon has a tint to it, we can normally refinish in the same colour.

This will vary massively on the part in need of being repaired. Often aftermarket parts are cheaply made which likely would be cheaper to replace than repair. For higher end, more expensive or rare carbon fibre parts, more often than not it absolutely does make sense to repair as the cost to replace is extremely high or the part is no longer production. We try to cater a repair to the budget of the customer, but we won’t offer a cheap solution if it means compromising the end result.

Sometimes yes depending on where the damage is and the possibility to reinforce. If the part is enclosed, it makes it very difficult to repair behind the damage point and reinforce to suitable level. More often than not however, if we can gain access behind the part, we can make the part as strong or even stronger than before. Carbon manufacturers will only use a handful of layers of carbon, we can add many more layers if required which will increase strength massively.

You can either drop the part off yourself or choose a courier to transport the part to us. We use Parcelforce large for most UK items as they will accept parts up to 2.5 meters in length. If being shipped to us, we do recommend using bubble wrap to protect the part itself along with a cardboard box to ensure the part doesn’t suffer any more damage during transit. If you need help with this element, please do get in touch to discuss as we may be able to help.

Sadly not. The repair process even if it is a simpler and more minor amount of damage, it will still require days of sanding, resin infusing and lacquering. In some cases, we can remove the part from your car here at our workshop (for an additional charge) and you may be able to drive away for a number of weeks until ready to refit.

Although we are capable of removing and disassembly, we prefer not to store any other parts and request the carbon is delivered or dropped off to us in bare form. By this we mean any other elements removed that could get in the way (fog lights, brake lights, trims, cables, fixings etc).

We get asked this quite a lot and the answer is mostly yes. We use specialist high temp resin and cure the part to have the ability to cope with high temperature demands. Often re-finishing/lacquering can be more complicated, but we do have methods to manage this depending on the application.