Extended Servicing & Maintenance

Extended Servicing & Maintenance

Keeping Your High Performance Vehicle Running At It's Best

To complement our inspection offerings here at Carbonwurks we are also able to offer a wide range of track-biased maintenance options for your car, whilst manufacturers often have a detailed service schedule for owners to adhere to its worth noting that this is geared towards the lower stress scenario of life on the road rather than circuit usage!

Increased servicing is most suited to modified vehicles or cars regularly driven in a spirited manner, it’s important to pay attention to the basics when it comes to track car maintenance.

Regular Maintenance

Engine Oil

Changing the engine oil in a track car is of utmost importance for several reasons. Firstly, track driving subjects the engine to extreme conditions, including elevated temperatures, increased RPMs, and heavy loads. These factors can cause the oil to break down and lose its lubricating properties over time. Regularly changing the engine oil with the recommended high-performance oil ensures that the engine receives the necessary lubrication and protection it needs for optimal performance and durability.

Performance engine oil is specifically formulated to withstand the extreme conditions experienced on circuit, such as elevated temperatures and heavy loads. This ensures optimal lubrication and protection for the engine, reducing wear and tear and extending its lifespan. Additionally, performance engine oils have enhanced viscosity properties, allowing them to maintain consistent oil pressure even under extreme operating conditions.

Brake Fluid

Changing brake fluid in a car destined for track is crucial for supporting optimal braking performance and safety. During track sessions, the brakes are subjected to intense heat and stress, causing the brake fluid to reach high temperatures. Over time, this can lead to a decrease in the fluid’s effectiveness and the formation of air bubbles, resulting in a spongy brake pedal feel and reduced braking power or even failure all together.

Regularly changing the brake fluid helps to remove any moisture or contaminants that may have accumulated in the system. By replacing the brake fluid with fresh, high-performance fluid, you ensure that the system is free from moisture and contaminants. This helps to support consistent brake performance, reliable stopping power, and a firm brake pedal feel, even during demanding track sessions.

Extended Maintenance

Beyond the basic requirements stated above there are several key components that feature serviceable parts or fluids which should be taken into consideration when preparing your car for track. Commonly some of these parts/fluids would be regarded as lifetime fit or fill by the manufacturer but the reality of the harsh extremes of a race circuit is that the integrity of all these parts is tested to a far greater level than they would be under normal road use!

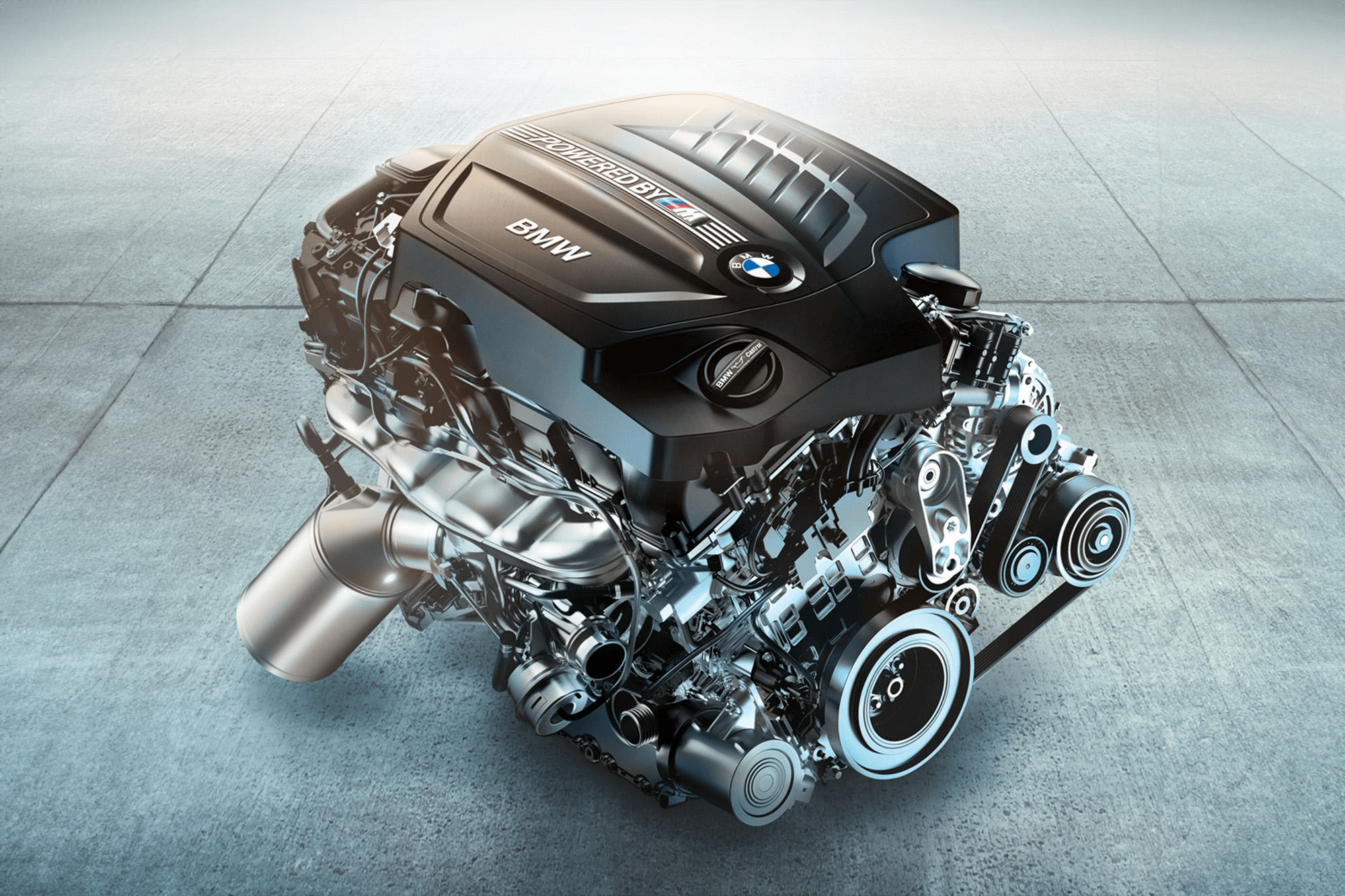

Engine

Air Filtration, Fuel Filtration & Injection, Spark Plugs, Coolant and Valve Clearances are all regular service items that typically dictate the long-term health of an engine and would form part of an extended service schedule. Recommended intervals for such items differ dependent on manufacturer but it’s good practise to follow a schedule of shorter intervals when it comes to your track car for the best in terms of reliability and peace of mind. It’s also important not to forget the servicing requirements of aftermarket air filters; high-flow, oiled air filters require periodic maintenance to maintain their efficiency and prevent any potential airflow restrictions.

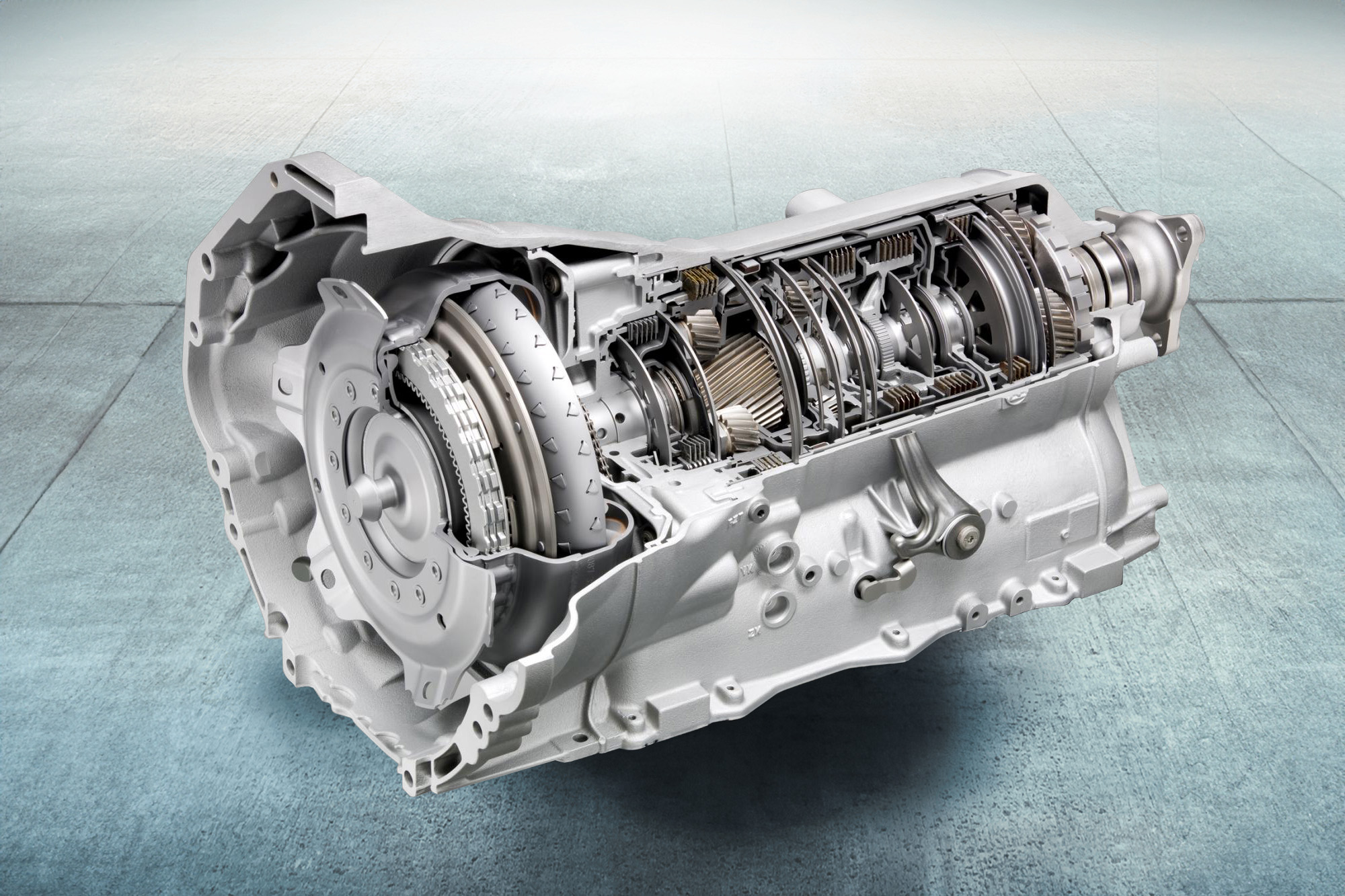

Drivetrain

Gearbox Oil, Differential Oils and Steering Fluids all form part of the extensive list of lubricants that are the lifeblood of the major moving parts of a car and are all a worthwhile consideration when it comes to planning the maintenance of your track car. Being subjected to elevated temperatures and pressures out on circuit can lead to accelerated degradation of these fluids which unchecked can lead to premature failure of major components which can not only be prevented by changing these fluids

Alignment

Probably one of the most overlooked areas of track car maintenance, geometry checks are essential for optimizing the performance and handling characteristics of any track car. By ensuring proper weight distribution, maximizing tyre grip, enhancing stability, and improving steering response, correct alignment settings contribute to a safer, more predictable, and ultimately faster track experience. This is relevant to any vehicle regardless of its level of modification but is guaranteed to unlock the potential of any steering or suspension upgrades you may have chosen for your car.