Vehicle Geometry Explained

Vehicle Geometry Explained

Why It's Important On The Road & The Track

Whilst we have our main Wheel Alignment & Geometry page showcasing the services we can offer we wanted to dig deeper into why it’s so important for those that really want to ensure their cars perform the best both on the road and the track!

Suspension geometry is designed to engage the tyre with the tarmac and ensure that the maximum amount of grip is being extracted from it during cornering, acceleration and braking. Optimising the alignment and movement of all the combined elements of suspension geometry results in a car that handles well, delivers consistent tyre wear and positive driver feedback, resulting in a fast and competent vehicle.

Why Alignment?

What Changes Can Be Made To Your Wheels

Alignment is the term used to describe the specific settings of the various geometry adjustments on any vehicle and is essential to the performance and safety of both competition and road cars alike. The checking and setting of a vehicle’s alignment requires specific equipment that is used to take various measurements comparing the angles and positioning of the wheels on each axle, once the initial measurement is taken these values can then be compared to set data published by the manufacturer and the geometry adjusted to suit. For competition cars where significant factors such as ride height will have been drastically changed, these settings will serve as a baseline from which more refined adjustments can be made to extract maximum benefits from the vehicle’s upgraded componentry.

In a world where road surfaces are perfectly smooth it would still be advised to have alignment checked on a yearly basis or with the replacement of tyres, suspension and steering components – for context a wheel that is just 2mm out of alignment equates to dragging the tyre sideways for 4.5 miles every 1,000 miles covered, reducing fuel consumption by up to 7%. The reality is that due to poor road conditions approximately 40% of cars on the road are carrying suspension damage that requires rectification (The AA, 2017) and with 24% of MOT failures being due to tyre-related faults caused by suspension or steering problems the requirement for having your alignment checked is probably far greater than you think!

When it comes to upgrading your track car you could choose the best suspension parts in the world and fit them your car and still be beaten by budget suspension that has been set up and aligned properly. You could be aligning your car to best suit new parts or selecting upgrade components to unlock geometry adjustments that aren’t possible in standard form, alignment is completely customisable. Refining setup according to your vehicle’s modifications and use as well as to your driving style and desired level of feedback, will make the car feel more predictable in corners and increasing stability in straight lines. When it comes to competition use, particularly in a single make series restricted to control parts, this alone can be enough to give you the winning edge!

Most importantly an accurate alignment will make sure that your steering wheel is straight!

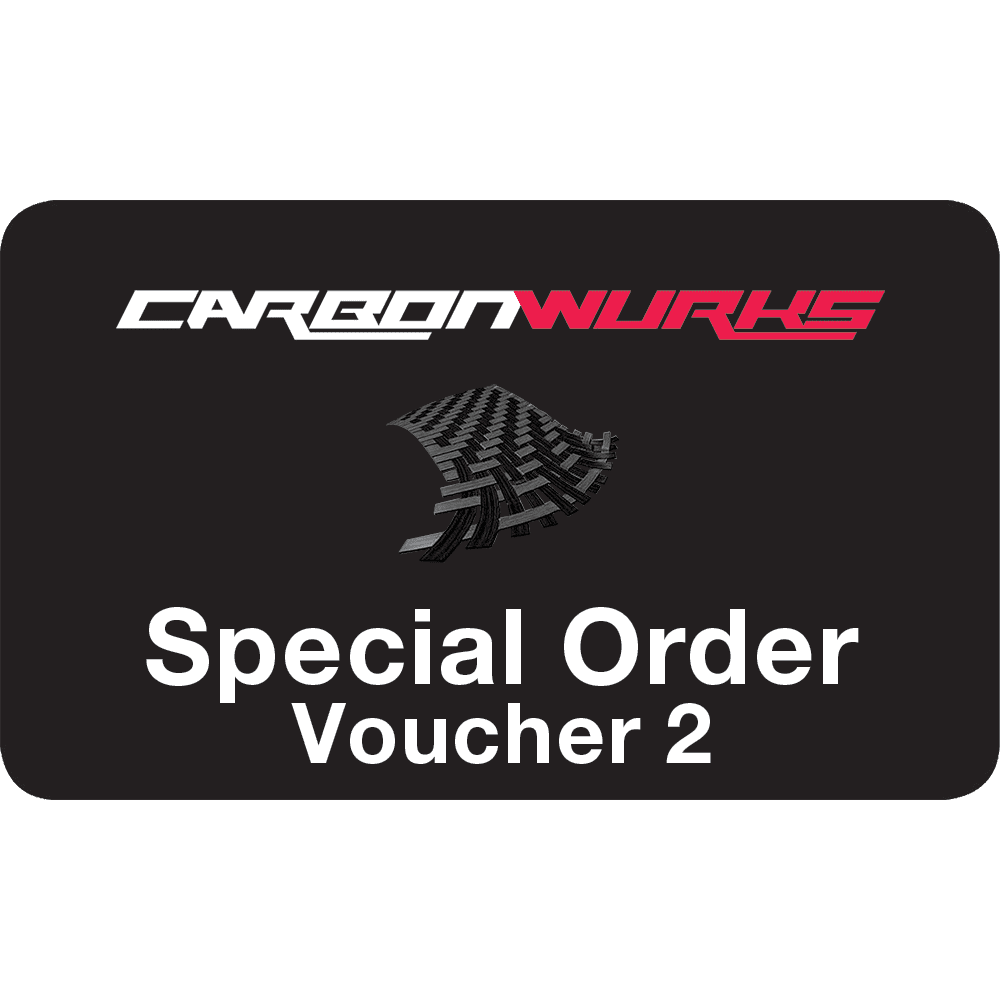

Toe

Parallel Tyre Alignment

Toe is the most commonly adjusted geometry value, often referred to as tracking, it is the measurement of angle of the wheels in relation to the centreline (front to rear) of the car where a wheel angled away from centre has toe-out and one angled toward the centreline has toe-in. Toe influences three major areas which are: corner entry handling, tyre wear and straight-line stability.

Toe-in on both front and rear axles provides the greatest amount of straight-line stability, this is because any disturbance in the steering pulling the wheel rearward would cause an outward steering motion which would simply straighten the wheel from its original toe-in. Excessive toe-in will cause increased wear on the outside edge of the tyre. Zero toe as you would expect is the most neutral setting with minimal tyre wear and the least amount of frictional losses as there is no tyre scrub when driving in a straight line.

Toe-out is commonly used on the front of track cars as it improves turn-in response, this is because the inside wheel is already pointing into the corner. It also helps to improve rear end grip when used at the rear and acceleration when implemented on the driven axles. The trade-off to these gains is instability at speed, a car set up with toe-out will be twitchy and as a result will start to feel nervous at speed. Too much toe-out at the rear will also induce oversteer in corners, where the rear of the car wants to rotate past the front and will lead to increased wear on the inside edge of the tyre.

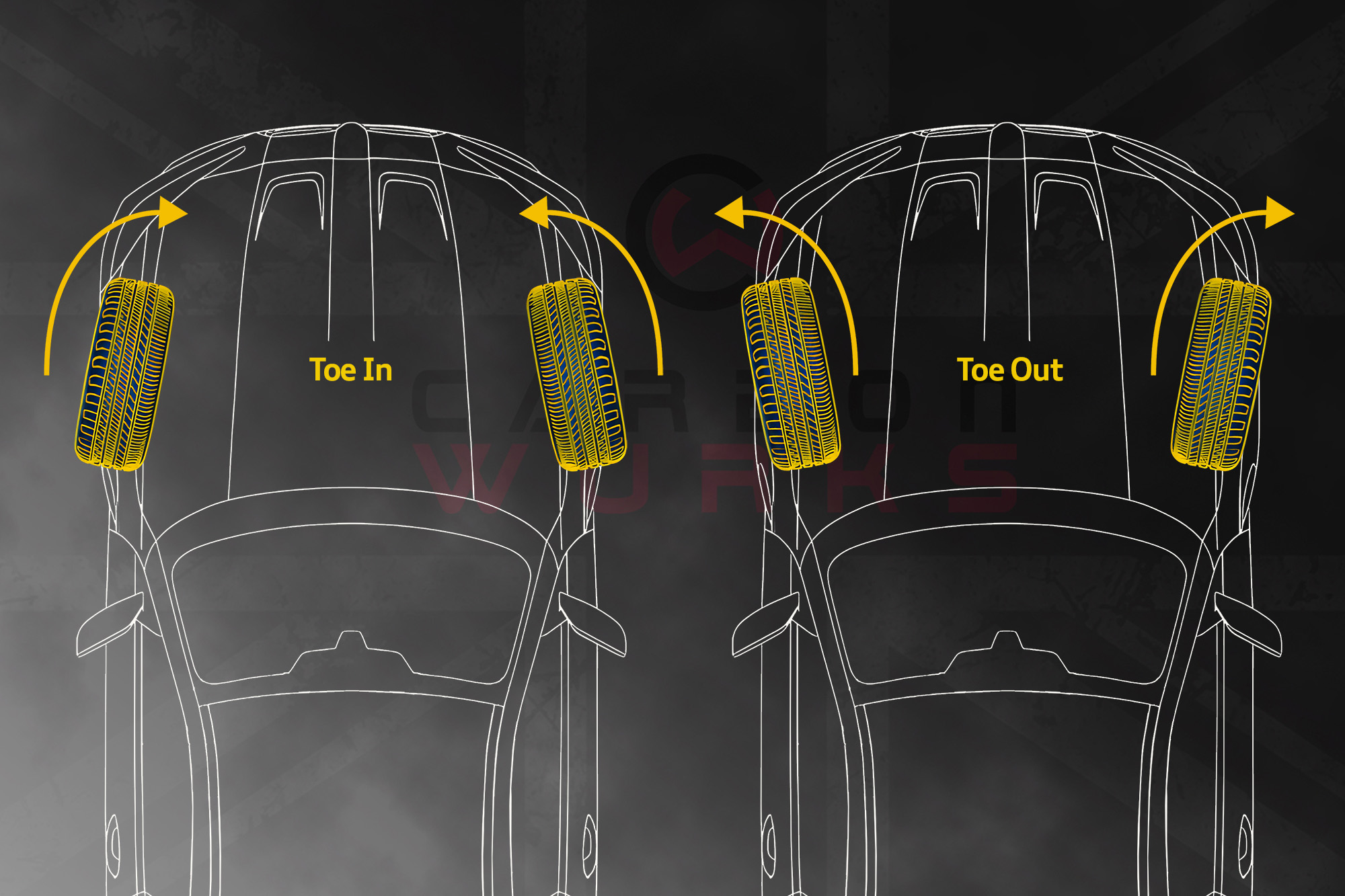

Camber

Inward or Outward Tyre Tilt Angle

Camber refers to the vertical positioning of the wheels of a car determining whether the top of the tyre points in towards the centre of the vehicle or outwards away from the car. Camber dictates how much of the tyre is in contact with the tarmac and increasing the amount of negative camber (lean in towards centre) will improve handling and increase grip when cornering at speed.

Zero camber indicates that the wheel is mounted perfectly vertical – this sort of neutral positioning puts the full contact patch of the tyre in contact with the ground which is safer for road use and in terms of performance beneficial to straight-line acceleration. Positive camber is the least common setting – rarely used in motorsport and only found in road cars which suspension damage, mounting the wheel with the top of the tyre pointing out can be beneficial in situations where heavy loads are carried which will act to neutralise the positive camber.

So why negative camber? Adding negative camber, particularly on the front axle, works to improve the amount of the tyre’s contact patch engaged with the tarmac mid turn. When high speed cornering the weight of the vehicle combined with the lateral load causes the car to roll in turn pushing the outside wheels towards positive camber, setting up with negative camber from the outset counteracts this reaction and provides the maximum amount of grip available from the tyre and reduces the chance of the tyre wearing unevenly.

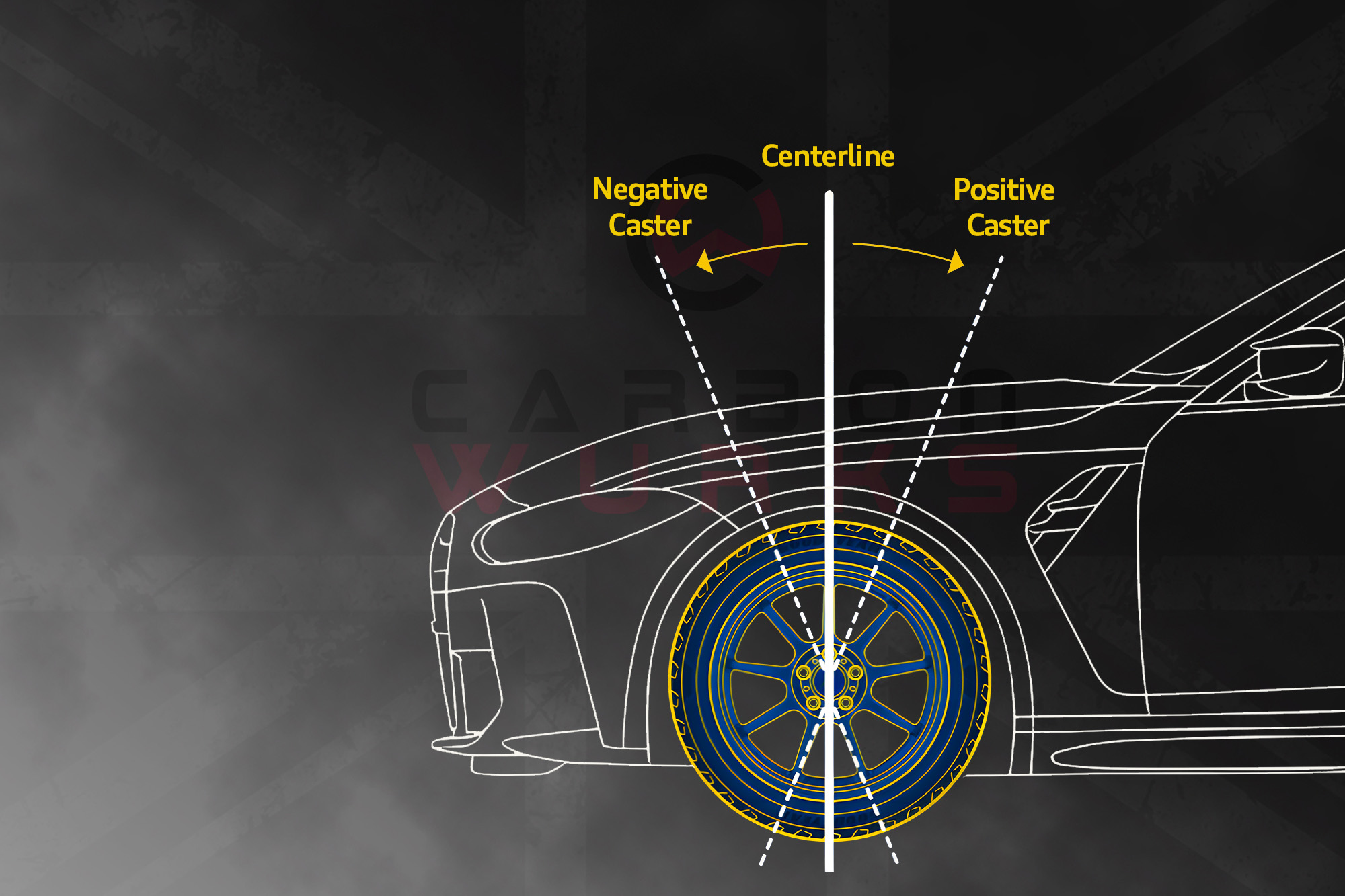

Caster

Steering Axis Tilt

Caster is a more technical measurement that indicates the position of the steering axis relevant to the vertical ‘zero’ centre of the hub assembly when viewed from the side of the car. Much like camber it’s possible to set positive, neutral and negative caster where positive caster is the most desirable. It’s not often that a car will feature caster adjustment from factory but it is achievable with adjustable suspension components.

Neutral caster is when the steering axis or pivot is dead centre of the wheel/hub assembly and exactly vertical as viewed from the side, it provides a safe level of feedback particularly when approaching the limits of grip and has the ease of steering of negative caster without the instability. Negative caster has very limited advantages, the most prominent being a very low amount of steering input required but with the significant drawback of little to no feedback and increased instability due to the ease with which the wheels can turn.

Positive caster has a number of advantages with only the one minor disadvantage of requiring greater steering input, however, with power steering this issue is minimal. It sees the steering axis tilted back from centre where the top upright mounting point is more rearward of the car than the bottom mounting point as viewed from the side. With positive caster the vehicle gains increased self-centering characteristics meaning the steering naturally wants to return to centre providing greater stability at high speed and enhanced control on corner exit. The right amount of positive caster also improves turn-in encouraging the car to rotate on entry and it also helps with the change of camber during steering by effectively leaning the car into the turn.

Corner Weighting

The amount of weight or load on each wheel

Corner weighting is refining weight distribution across the car to balance the weight and resulting grip levels of each wheel, it is relevant to all cars but usually practiced only in conjunction with height adjustable suspension as it can be achieved without adding weight to the vehicle. The ideal outcome would be an equal 25% split on each wheel however that is rarely the case but having an even split side-to-side on each axle will avoid undesirable lockups, loss of traction and the nervousness experienced when there is a weight imbalance. Corner weighting is also the most accurate way to setup height adjustable suspension as it avoids inaccuracies due bodywork and suspension mounting differences across the car.

Adjusting the corner weights of a car is usually achieved by adjustment of the spring platforms on height adjustable suspension or alternatively by relocating certain components in the car such as the battery. It requires the use of accurate corner weighting scales and a perfectly flat set-up space or ‘flat patch’, as an uneven surface would skew the readings a level area is key to an accurate setup. The car should ideally be settled onto the corner weight scales carrying the drivers/passenger’s weight located appropriately and filled with fuel, an initial reading can then be taken assessing the cross-weights before making adjustments to achieve the best possible weight distribution. This is probably one of the most cost-effective methods of tuning the handling of your car.

Ride Height

The distance of the car to the ground

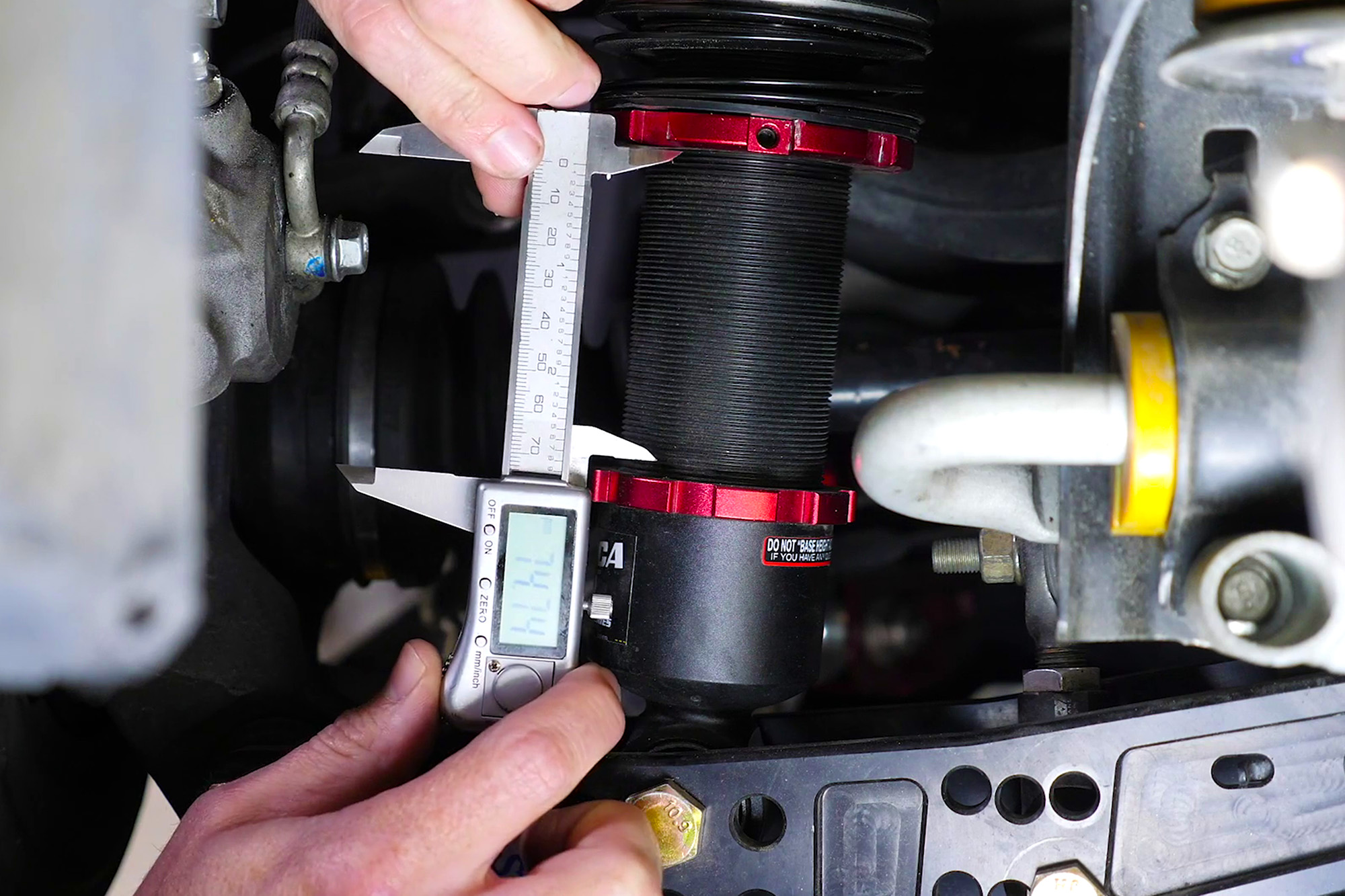

Whether through an adjustable spring kit or race specification multi-way coilovers, gaining height adjustment on your car is a significant step forward in tuning the setup of your car. The benefits of having control over your ride height are more than just aesthetical – reduced ride height generates increased downforce and independent adjustment at each corner allows any axle imbalance to be dialled out resulting in a more stable and predictable car. Typically ride height adjustment is provided in the form of an adjustable spring platform that can be raised or lowered over a threaded body offering a range of possible right heights as opposed to the one fixed position offered by a spring alone.

The process of ride height adjustment requires a level surface upon which to set the car and take accurate measurements from fixed reference points (typically wheel centre to wheel arch) that can then be referenced to the opposing side of the same axle. It’s also necessary to lift the car off the floor to remove the load from the suspension to enable easier adjustment, sometimes it’s also necessary to remove the wheel in order to access the spring platform. With measurements taken the spring platform can then be adjusted, using fixed reference points allows setting to be matched on corresponding corners before making fine adjustments to achieve the desired ride height.

Ride height adjustment provides a suitable baseline for corner weighting to be carry out which is the most accurate method of setting ride height, accuracy can however be improved by choosing to load the vehicle with specific amounts of fuel or weight to represent occupants being present in the car. One of the most important parts of ride height adjustment is to make sure the vehicle is fully settled on its suspension before measurements are taken, at very least it should be rolled forward and back after being set on the ground or best case performing a road test between adjustments.

The Pricing

Ensuring You Get The Best Setup For Your Vehicle

If after reading and learning a bit more in-depth about the world of vehicle geometry and why it’s so important both on road and on track that you want to get your vehicle sorted, please see below on pricing and how to get get in touch.

Pricing varies depending on the service you require and the age/condition of your suspension components. We have broken this down into 3 separate services to try and keep it as simple as possible.

For all the alignment services below you will receive a Before & After PDF print-out (or email) of the before and after alignment results

Option 1

Wheel Alignment

From £95*

This service is for a full 4 wheel alignment and offers adjustment for front & rear toe, where the vehicle allows for this (For example some cars only allow for front toe adjustment). This also includes a suspension health check prior to starting.

Typically this should take approximately 1 hour to complete.

(If Camber & Caster are required this will require extra time and cost)

Option 2

Ride Height Adjustment

From £265*

This service includes all the benefits from option 1 with additional ride height adjustment to your suspension setup. Depending on requirements with your car, we will discuss and set up your ride height based on this information. We can also simulate driver and passenger weights if required.

Typically this should take approximately 2-3 hours

Option 3

Corner Weighting

From £325*

This service includes all the benefits from options 1 & 2 as well as a corner weighting service. Using individual corner scales, we will balance and level the weighting across the axles with simulated driver and passenger (if required) weighting.

Typically this should take approximately 4-5 hours

*We show all our prices starting from due to some vehicles needing additional work before adjustments can be made. For instance some components may be seized and require freeing or trim panels may need to be removed to gain access. For any work required to get the vehicle ready for alignment is charge out at £90 per hour including VAT on top of the prices and timescales mentioned above.

so here's what's

Needed From You!

To get your vehicle booked in with us for either wheel alignment, ride height adjustment or corner weighting please fill in the contact form below: